Industry needs to take risks on supercomputing, Rob Akers tells Adam Duckett

IF YOU’VE heard the term metaverse, it’s likely been linked to Facebook’s parent group rebranding itself as Meta and gambling on a near future where many of us slip on a pair of virtual reality (VR) googles to shop and share experiences in an immersive digital world. Love or loathe the idea, a suite of advanced technologies are converging to help bring this virtual vision to reality, and whether you plan to enter the metaverse during your own time, there’s a growing chance you will while at work.

To understand what this future might look like, I spoke to Rob Akers, director of computing programmes at the UK Atomic Energy Authority (UKAEA), who is using the industrial metaverse to accelerate engineering. “We’ve got a team of people working on everything from exascale supercomputing problems to artificial intelligence problems, effectively trying to work out how to design in silico [on computers] rather than have to do huge amounts of real-world testing,” Akers says.

Earlier this year, UKAEA, the University of Cambridge, and tech firms Dell and Intel joined forces, declaring the industrial metaverse essential for the development of the UK’s fusion prototype power plant, known as STEP, which is pushing to put power on the grid in the 2040s.

UKAEA

Rob Akers standing inside the JET test facility

Engineering in the metaverse

While it’s easy to dismiss the metaverse as a fad – after all, the promise of virtual reality technology has been hyped for decades but never quite arrived at the scale promised – the convergence of digital twin technology, artificial intelligence, machine learning, the internet of things, blockchain, and cloud and edge computing means we’re on the cusp of a significant shift, and one that Akers says is crucial to us achieving a cleaner future.

“I think it is the only way that we’re going to be able to achieve our goals for delivering net zero.”

A report published earlier this year by the MIT Technology Review (https://bit.ly/3GlCrfw) concluded that the emergent industrial metaverse will enable improved design and engineering, more extensive testing and validation, virtual commissioning, and enhanced operations.

To glimpse an early form of the future Akers is striving towards, we can look to Nvidia and its Omniverse service. You may have seen the chipmaker’s name printed on a sticker on your laptop – but you may have missed the news that Nvidia’s high-end chips have powered the last 12 months’ rapid development in artificial intelligence. This has propelled Nvidia into the top ten most valuable companies in the world and led the US government to ban the export of some of its high-end AI chips to China, Russia and Iran to curb those countries’ military ambitions.

Omniverse allows users to collaborate in what it describes as a full fidelity virtual world – it is a slick way of using the modern internet to stitch together people, processes, digital tools, and facilities such as the world’s largest supercomputers. Engineers and other specialists can access the technology remotely, including through Microsoft Teams, and work together in real time to build physically accurate visualisations and simulations of products, production lines and whole plants. Among its video case studies, BMW shows how it’s using the platform to design car factories faster and more cheaply by connecting workers from across the globe, pulling in and combining data from disparate sources.

Siemens is using Omniverse to create digital twins of its turbines’ heat recovery steam generators to simulate how steam and water flows through pipes as it seeks to predict corrosion and better plan its maintenance operations. It says the technology can reduce corrosion estimates from weeks to hours and could cut downtime by 70%.

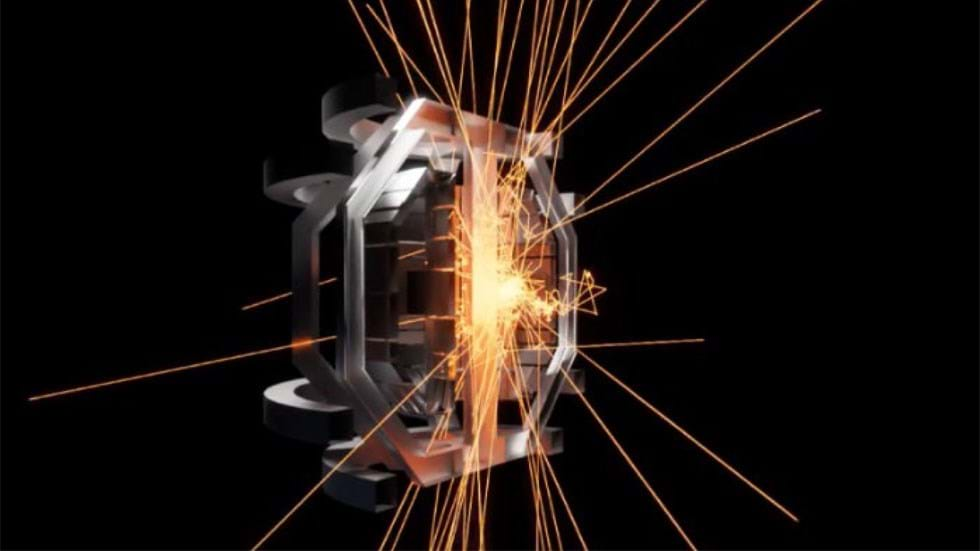

Meanwhile, the UKAEA is exploring the use of Omniverse to accelerate the design of a fusion reactor, creating a so-called digital twin of all the reactor components, the plasma, radiation-induced microstructural damage across the plant, and the control and maintenance systems. They are working to connect separate 3D design, engineering, and simulation tools so they can collaborate on a “single source of truth”. Developers at the University of Manchester have created Omniverse plugins to pull in data from industry simulation programmes including Monte Carlo Neutronics Code Geant4 which simulates the neutron transport that carries energy out of the reactor, and for the Jorek plasma code which simulates light emission to help assess the state of the plasma. They expect that once built, the physical power plant will be synchronised with the digital twin using real-time streams of sensor data to allow developers to test changes virtually before deploying them in real life. This will include programming and training maintenance robots in simulations before the physical ones are commissioned.

University of Manchester / Nvidia

Geant4 simulation, driven by Omniverse of neutron transport inside a tokamak fusion reactor

UKAEA

A Jorek simulation is helping simulate the state of plasma inside its containment vessel as engineers upgrade the Mega Amp Spherical Tokamak (MAST-U) at the Culham Centre for Fusion Energy

It could look like technology straight out of ‘Star Trek’ where a human asks a computer to solve a problem through voice prompts – we have already seen tantalising glimpses of how large language models can act as an interface to design optimisation workflows

Peering further into the future

This news is republished from another source. You can check the original article here